Oil and Gas

The Oil and Gas Industry greatly benefits from the non-corrosive alloy layer Eon Coat creats as it is applied to metal equipment that is constantly subjected to extreme environmental conditions, hydrocarbons and chemicals. The annual cost of oil and gas corrosion damages due to equipment failure and lost production time can be astronomical. The Off Shore Drilling Industry uses Eoncoat to protect all the metal structures used in the drilling process from supply boats, oil tankers and drilling rigs themselves, reducing down time and continual recoating. Marine industry machinery must function in a highly corrosive environment. Below the water line, ship hulls and docks battle against corrosion caused by constant submergence in seawater. Above the water line, the corrosive environment is not much better as wind and saltwater work together to rust even indoor equipment on ships and marinas. EonCoat’s corrosion protection stops rust even in such harsh conditions. EonCoat is an excellent option for use as a primer. It has an inert porous surface with a pH of about 10 so almost all paints bond to it easily without further prep.

The Oil and Gas Industry greatly benefits from the non-corrosive alloy layer Eon Coat creats as it is applied to metal equipment that is constantly subjected to extreme environmental conditions, hydrocarbons and chemicals. The annual cost of oil and gas corrosion damages due to equipment failure and lost production time can be astronomical. The Off Shore Drilling Industry uses Eoncoat to protect all the metal structures used in the drilling process from supply boats, oil tankers and drilling rigs themselves, reducing down time and continual recoating. Marine industry machinery must function in a highly corrosive environment. Below the water line, ship hulls and docks battle against corrosion caused by constant submergence in seawater. Above the water line, the corrosive environment is not much better as wind and saltwater work together to rust even indoor equipment on ships and marinas. EonCoat’s corrosion protection stops rust even in such harsh conditions. EonCoat is an excellent option for use as a primer. It has an inert porous surface with a pH of about 10 so almost all paints bond to it easily without further prep.

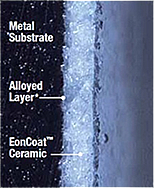

EonCoat chemically bonds to metal substrates, converting metal surfaces to bonded ceramics. This newly formed ceramic surface is dense, hard, nearly insoluble, and impervious to oxygen and moisture. In addition to its superior protection properties, EonCoat greatly reduces the danger of working with highly volatile compounds because it has no VOC's or HAPs. It cannot ignite and because it does not create any toxic vapors, the odor, headaches, and nausea often associated with polyurea and polymer coatings are completely eliminated. EonCoat provides greater corrosion resistance for equipment, greater health protection for workers, and greater protection to the environment by reducing the carbon footprint by 90% and has no hazardous waste for disposal.

EonCoat chemically bonds to metal substrates, converting metal surfaces to bonded ceramics. This newly formed ceramic surface is dense, hard, nearly insoluble, and impervious to oxygen and moisture. In addition to its superior protection properties, EonCoat greatly reduces the danger of working with highly volatile compounds because it has no VOC's or HAPs. It cannot ignite and because it does not create any toxic vapors, the odor, headaches, and nausea often associated with polyurea and polymer coatings are completely eliminated. EonCoat provides greater corrosion resistance for equipment, greater health protection for workers, and greater protection to the environment by reducing the carbon footprint by 90% and has no hazardous waste for disposal.

Unlike most coatings, EonCoat does not require labor intense surface preparation. A commercial blast to NACE 3 or NACE 5 water jetting is sufficient preparation to apply Eon Coat. Slight oxidation of the metal substrate actually helps the EonCoat chemically bond to the metal substrate creating the protective alloy layer and flexible, durable ceramic. EonCoat is 100% chemical bond not a mechanical bond. Other traditional polymer coatings require a bright metal NACE 1 blast to try to achieve the best mechanical bond, usually at best bonding 60%. This reduces preparation time and saves money. The one coat system dries to the touch in minutes and is fully cured in two hours. Outages can be costly. EonCoat makes it possible to protect assets and get equipment back in service faster than with traditional coating systems. The quick return to service is very critical key for all the Oil and Gas Industry but especially on an Off Shore Drilling Rig.

Fast Return to Service saves Time and Money

Frac Tanks are another benefactor to Eon Coats outstanding protective properties. EonCoat provides a non corrosive barrier that is very durable and impact resistant. EonCoat is a quick setting one coat system with two layers of protection. As Frac Tanks are continually moved and subjected to rough handling the chemical bond, impact resistance and flexibility of EonCoat make it the perfect solution for Oil Field Service Companies to keep their fleet of Frac Tanks in good working order without costly yearly recoating they endure with typically polymer coatings.

EonCoat Lasts Longer Than Polymer Coatings

EonCoat is completely inorganic, lasting the way other inorganic things do. Inorganic compounds, like rocks, are very durable weathering the elements over time. There are no carbon chains to break down so it cannot corrode.

Before EonCoat nearly all coatings were organic “polymers,” which comes from the Greek words, poly (meaning many) and meros (meaning parts). Polymers are chains of many parts that are all the same linked together by a backbone. The backbone of organic polymers is carbon atoms. Polymers, long chains of carbon atoms with various things attached at different points to the carbon atom, break down with time and heat. For example, breaking down the carbon chains is the way we make gasoline from crude oil. We break down, or crack, the carbon chains.

Exposure to heat, sunlight and the passage of time causes all carbon chains and thus all polymers, including polymer paints and coatings, to break down. Because EonCoat is inorganic and has no carbon chains it does not break down, therefore lasting longer than polymer coatings.

Ductile and Flexible

EonCoat ceramics have more flexibility or ductility than is needed to handle the typical movements of steel - including flexing, expansion, and contraction. EonCoat stretches 19% prior to failure, more than enough to handle the ordinary movements of steel.

Quick Cure

EonCoat sets rapidly to enable quick buildup of the coating layer, making a one-coat application practical. EonCoat is so fast setting it is possible to build to a thickness of ¼” in a single coat without run or sag. This dramatically reduces labor costs when recoating frac tanks.

One Coat but Two Layers of Protection

At the point of contact, EonCoat creates a chemical reaction that alloys steel. A passive layer forms that can no longer corrode, making the elements (rain, salty air, hot sun) a non-factor since alloyed steel cannot rust. The ceramic coating then acts as a secondary protection on top of this passive layer protecting the Frac Tank.

Tremendous Durability, Impact and Abrasion Resistance

EonCoat provides excellent durability, impact and abrasion resistance withstanding over 160 inch pounds of force. EonCoat has undergone extensive tabor testing of the coating to test abrasion and wear. What is wear? ASTM International defines wear as "damage to a solid surface, caused by the relative motion between that surface and a contacting substance or substances". Usually the material loss occurs gradually from exposure to repetitive motion. Abrasion is the action that causes the wear. ASTM defines abrasion as "the wearing away of any part of a material by rubbing against another surface". The Tabor test allows us to compare the relative hardness and durability of different coatings. EonCoat’s protective ceramic layer will endure 3,500 cycles before one mil of coating loss compared to the best epoxies, which take 1,200 cycles to remove one mil of coating. The ceramic coating provides an excellent barrier protecting the non-corrosive alloyed layer withstanding all the handling and abrasion abuse Frac Tanks endure. This saves services companies time and money spent on continually recoating frac tanks.

Oil Refineries have many surfaces that can benefit from coating with EonCoat, steel holding tanks, steel piping, and concrete containment areas. Facility Managers are able to schedule coating jobs in occupied areas that could get done in a single day or weekend, instead of taking several weekends waiting for multiple coats of primer.

Upstream to downstream, above ground or underground, EonCoat is used by some of the world’s largest Oil & Gas companies to solve costly corrosion problems. If traditional systems worked – corrosion would no longer be such an expensive problem.

Turnaround time reduced by roughly 50%

A customer study from a leading petroleum company concluded that using EonCoat cut the number of shifts required to coat the average tank by half. Fewer shifts translate into fewer days out of service. Because EonCoat dries to the touch in about 5 minutes and requires only one coat, equipment can get back up and running almost as fast as the applicator can spray one coat. Also, pipelines do not need to cool down to coat exteriors saving time.

Salt Water Disposals subject their steel tanks to a highly corrosive mixture of salt water, hydrocarbons, and potential trace amounts of hydrogen sulfide or other acids. Long-term submersion in seawater will have no negative impact on the coating. EonCoat performs well in total submersion of salt water as it has been tested using NASA’s sea spray test.